Green Power

GA Solar Tour – Next Stop ALP!

Advantage Laser Products in on the Georgia Solar Tour (part of the national solar tour) this Saturday.

Advantage Laser Products in on the Georgia Solar Tour (part of the national solar tour) this Saturday.

For those interested in renewable energy. Attend the Georgia Solar Tour this Saturday. National tours also available, just go to nationalsolartour.com Advantage Laser is on the Tour in Atlanta (free soda)!!! http://www.gasolar.org/solar_tour.php. Experts from Empower will also be here to answer your technical questions.

Or if you want to bypass the entire tour, feel free to stop by from 11:00 – 2:00pm. We’ll be here with refreshments and a scissor lift to transport you to the solar array on the roof. We’ll also be handing out coupons for $20 off your next order.

We’re located at 1840 Marietta Blvd NW, Atlanta, GA 30318

New Energy Management System Saves Electricity and Money

In May we started working with Empower in install an energy management system to help reduce our demand peaks. We have two major sources of power demand, air conditioning and our toner collection system. Our toner collection system has a 30hp motor that pulls air (and toner) from all of our workstations. The system is oversized and probably pulls more juice than it should. When we first installed it back in 1998, we figured we would be building twice as many toner cartridges withing a few years and would need the extra workstations. And while we are doing well, we have not grown as fast as we’d hoped. But I digress…

The energy management system or EDGE as empower calls it, monitors our total power usage and if we start pulling more than 40kw EDGE adjusts the temperature by a couple of degrees, while rotating HVAC unit one at a time at the normal temperature. Once the toner collection system goes off (and usage goes below 40KW), the AC units are then allowed to bring the temperature back down.

The energy management system or EDGE as empower calls it, monitors our total power usage and if we start pulling more than 40kw EDGE adjusts the temperature by a couple of degrees, while rotating HVAC unit one at a time at the normal temperature. Once the toner collection system goes off (and usage goes below 40KW), the AC units are then allowed to bring the temperature back down.

By reducing our peaks, we can reduce our overall power rate. Our previous high peaks were around 70kw. We’re hoping the new system will have our peaks around 40kw. In addition we seem to be using less power as well.

Empower recently used us a case study. Read more about our energy management system.

Solar Array Working Great!

February was our first full month of solar power. As you can see we produced about 1,600kwh which is right on track with predictions. In the summer we should produce twice that. Our typical sunny day is producing 100KWH, but as you can see there are days where the array produces almost nothing. Maybe drought is good?

We’ve already avoided putting 1,822kg of CO2 into the atmosphere. That’s pretty cool.

And the survey says…

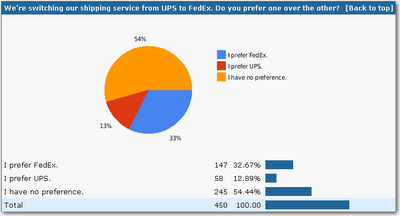

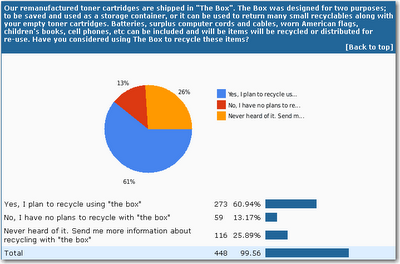

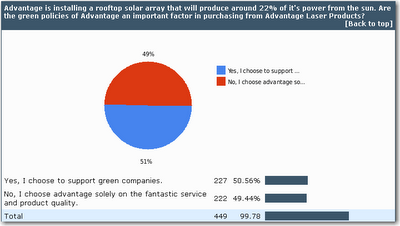

We recently polled our customers on a couple of questions and the results are below. Note only about 2.8% of all emails sent to customers resulted in a completed survey. I’m not surprised, we’re all bombarded with unnecessary email and completing a survey isn’t exactly a top priority. Still even if only a few people complete the survey, it’s helpful to keep a tab on the pulse of our customers. We had 37 Brother P-Touch printers to give away for people that filled out the survey, and 450 people filled out the survey. Sorry we didn’t have a printer for everyone, for those of you that didn’t get one – better luck next time! On to the survey…

UPS vs. FedEx – We’ve just switched to FedEx from UPS and while half of our customers seem indifferent between the two services, those that did have a preference prefered FedEx. I guess we made the right move.

Recycling with “the box” – this one surprised me. To date, we’ve had very little participation with recycling with the box. We’ve tried fliers with each “box”, but not much success. We recycle so many common items, but most people hopefully are recycling locally. Yet 61% plan to recycle with the box. Hopefully the survey also worked as a reminder that we offer this service and will recycle more and more with the box. Check out our box recycle flier and see all that can be recycled with “the box”.

Buying from environmentally conscious green companies – The survey we split 50/50 between those that prefer to buy green and those that buy based upon superior product and service. Luckily with Advantage, you don’t have to compromise. We are green and we provide the best products and service!

Solar Project – Day 7

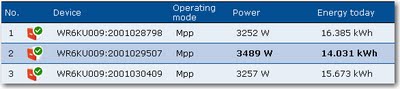

It’s been a week and we are now producing solar power, real green power delivered free from the sun! The array was installed in one day. It took another 2-3 days for the electricians to mount the inverters and run the conduit from the array to the inverters to our panel. Yesterday was sunny, so it was a good day to crank up the inverters and see what we were producing. We could have started it sooner, but it was rainy on Friday and the engineers from Empower didn’t want to launch on a cloudy day because there was still more testing to go and they wanted to see the array perform at full power. We’re producing 11KW of power right now at 11:20. That’s actual power delivered into our electrical system after any loses from the inverter.We actually have three 6KW inverters. Here’s some actual data from each inverter…

The SMA WebBox collects data from the inverters on power generated and CO2 emissions avoided. You can checkout our power production at anytime from our SunnyPortal. Right now it doesn’t show much power generated, but it will. The system isn’t real time and only gets updated every so often. Still it’s nice to be able to monitor the power generated by the system.

The SMA WebBox collects data from the inverters on power generated and CO2 emissions avoided. You can checkout our power production at anytime from our SunnyPortal. Right now it doesn’t show much power generated, but it will. The system isn’t real time and only gets updated every so often. Still it’s nice to be able to monitor the power generated by the system.

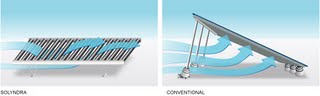

At this point there really isn’t much to do with the system. PV systems such as this are relatively maintenance free. Annual maintenance includes pressure washing the panels and the roof underneath the panels, as the Solyndra modules rely on the reflective surface of the white roof for 20% of their power generation. I’ll update in the future on the system performance promised vs. delivered. -Marvin

Solar Panel Project – Day 2

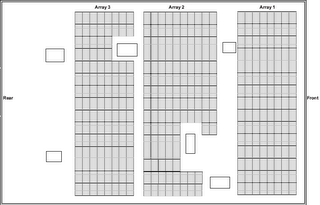

Day 1 of the solar panel project was really satisfying as we were able to install all of the solar panels in one day. At the end of the day we could see what we’d accomplished. Day 2 consisted of testing each of the 9 strings to make sure the were functioning properly. The plan was to get all of the strings jumpered and connected to the splicer box on the roof, but we ran out of cabling so that will have to be finished on Friday.

While we were on the roof, the electrician ran conduit from the roof penetration to the inverters (indoors). 3 SMA SunnyBoy inverters will do the job, but they take up way more wall space than I’d hoped. I have no idea where we will mount the inverters for future arrays. We went with three inverters to save money over buying one large inverter, but there is a space penalty.

Day 3 is a bit of a wash, as it’s raining, so nothing will happen on the roof. The electricians will be able connect the inverters to our panel. This is how the power gets into our system. We also wired the sunny boy webbox to the inverters which will enable us to monitor real time power production and see exactly how much power is generated by the system via a web browser.

Day 4 – assuming it’s sunny, we should be able to run the power from the splicer box to the inverters and crank it up. That’s the plan.

Advantage Laser Solar Panel Project

Day 1 of the solar panel project got off to a bad start. The crane started setting up at 9:00 and was ready to go, but we had no panels. The truck was already a day late and communication with the trucking company was terrible. First the panels were supposed to be there Monday morning, then Monday evening, then Tuesday morning at 7:00 sharp, then at 9:00 they were an hour out, finally the panels arrived at 2:00pm Tuesday. Meanwhile we had 10 people standing around with little to do.

Once the panels arrived, we got to work with the crane. We had 8 pallets of panels and two more pallets of support legs and other misc hardware. The nice thing about the Solyndra panels is they are so fast to install. Once we got trained on the assembly, we were able to have all 125 panels installed by 6:30 that evening. Yes, we did finish in the dark, but it felt good to get the panels installed.

Advantage Laser Installs 21.8KW Solyndra Solar Array